Technological properties of steel

1、 Castability

The ability of metal materials to obtain qualified castings by casting method is called castability. Castability includes fluidity, shrinkage and segregation tendency. Liquidity refers to the ability of liquid metal to fill the mold. The better the fluidity is, the easier it is to cast thin and delicate castings. Shrinkage refers to the degree of volume shrinkage of castings during solidification. The smaller the shrinkage, the smaller the deformation of castings during solidification. Segregation means that the chemical composition is uneven. The more severe the segregation is, the more uneven the performance of each part of the casting is, and the less reliable the casting is.

2、 Machinability

Machinability of metal materials refers to the ability of metal to accept cutting processing, and also refers to the difficulty of metal becoming a qualified workpiece after cutting. Generally, the machinability of metal can be evaluated by the roughness of the working surface, cutting speed and tool wear after cutting.

3、 Weldability

Weldability refers to the performance of welded joints with expected quality requirements obtained by common welding methods under specific structural and technological conditions. The weldability is generally judged according to the crack sensitivity generated during welding and the change of mechanical properties of the weld zone.

4、 Malleability

Forgeability refers to the property that materials will change shape without cracks when subjected to hammer forging, rolling, drawing, extrusion and other processing processes. In fact, it is a manifestation of metal plasticity. The higher the plasticity of metal materials, the smaller the deformation resistance, and the better the forgeability. The forgeability mainly depends on the chemical composition, microstructure, deformation temperature, deformation speed and stress state of the metal.

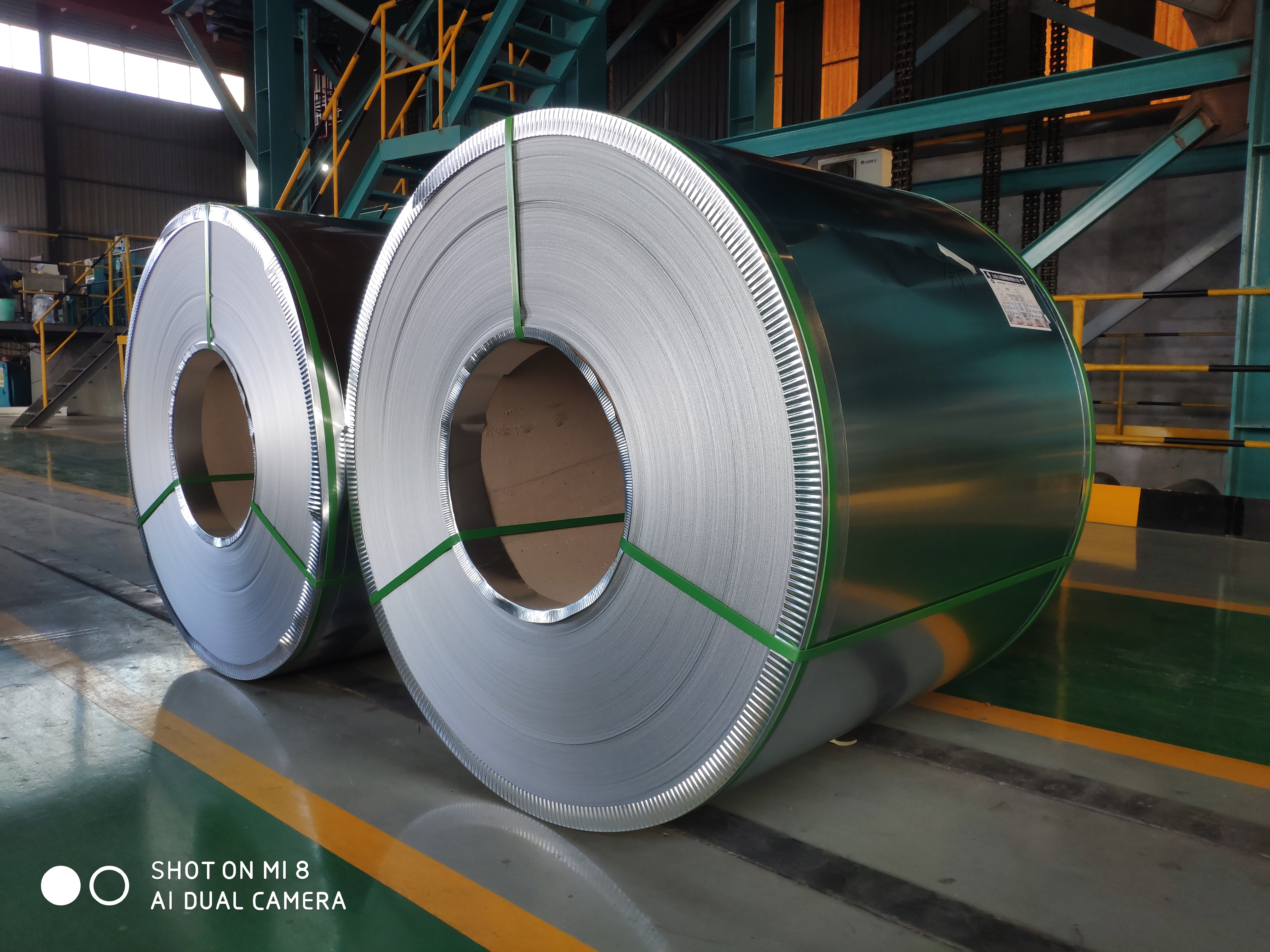

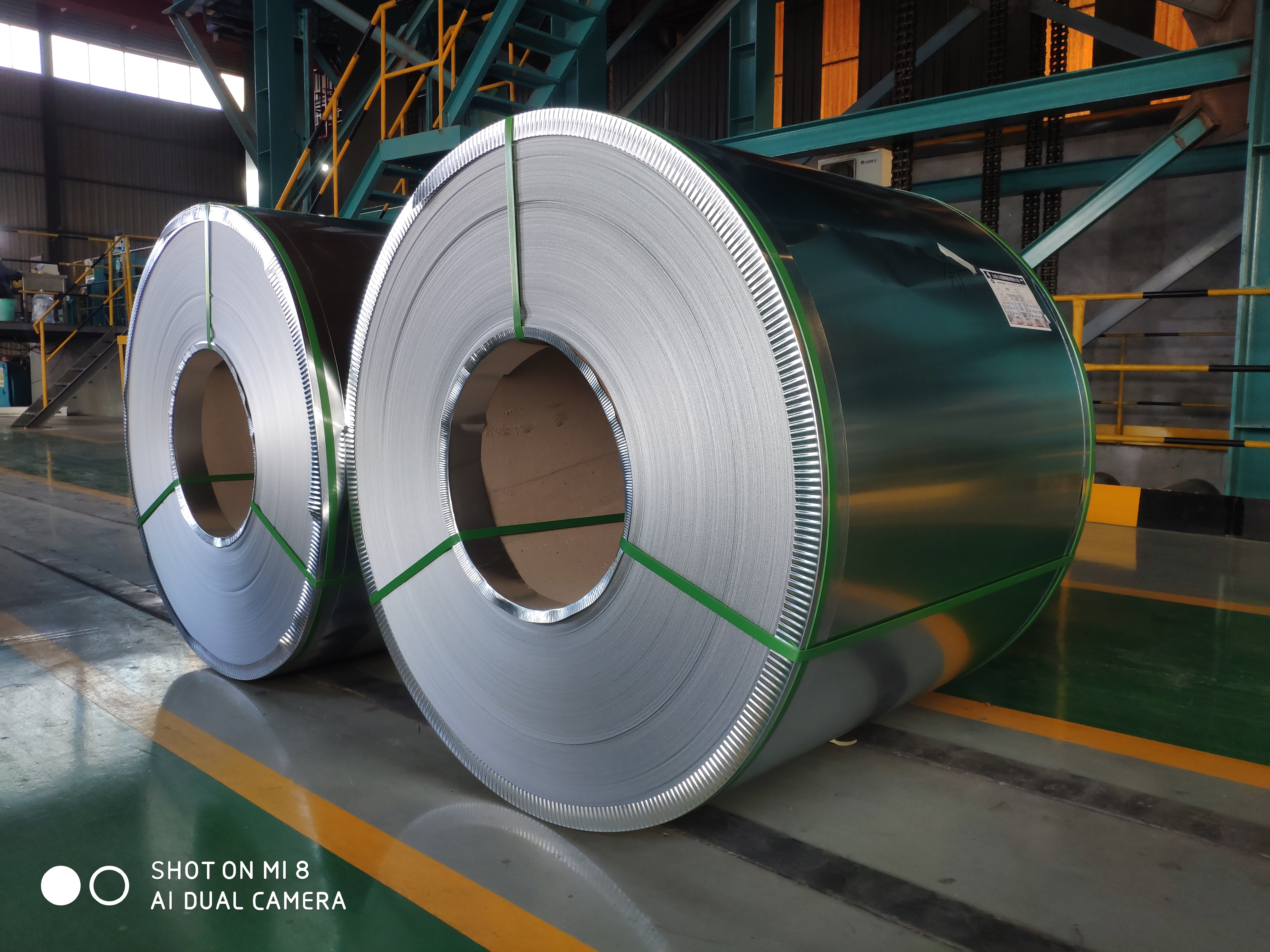

5、 Stampability

Stampability refers to the ability of metal to undergo stamping deformation without cracks and other defects. Many metal products are manufactured through stamping process, such as car shells, enamel blanks, pots, pans, pots and other daily necessities. In order to ensure the quality of products and the smooth process, the metal plates and strips used for stamping must have qualified stamping performance.

6、 Upformability

Upformability refers to the ability of metal materials to withstand upsetting deformation such as riveting and upsetting. The upsetting property of metal is determined by upsetting test.

7、 Cold bending

The ability of metal materials to withstand bending without cracking at room temperature is called cold bending. The greater the degree of bending that can be withstood before cracking occurs, the better the cold bending performance of the material will be.

8、 Heat treatment processability

Heat treatment refers to a process operation in which a metal or alloy can change its internal structure and obtain the required properties through certain heating, heat preservation and cooling methods within the solid state range. Heat treatment processability refers to the ability of metal to change its structure and properties after heat treatment, including hardenability, hardenability, temper brittleness, etc.